Hot Chamber

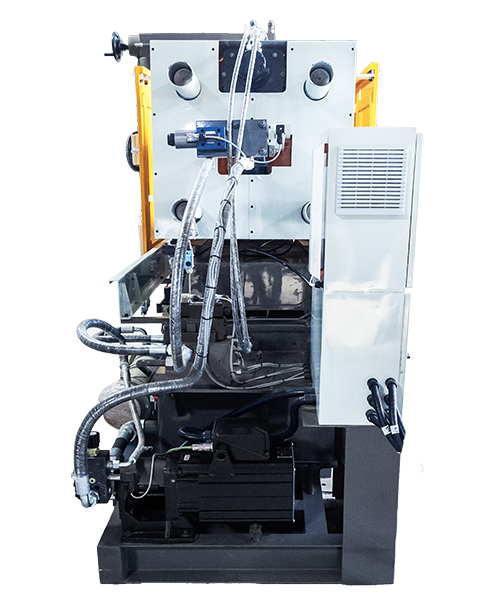

Our zinc die casting machines, ranging from 40 to 250 tons, are designed to deliver high-precision, high-volume production with consistent quality. Whether for small intricate components or larger industrial parts, this range offers the flexibility to meet diverse manufacturing needs. With advanced injection systems, robust locking mechanisms, and user-friendly controls, these machines ensure efficient operation, reduced cycle times, and superior casting accuracy.

From belt buckles and automotive fittings to electronics and hardware components, our zinc die casting machines provide the strength, durability, and surface finish required for modern applications—helping manufacturers scale production with confidence and reliability.

Model No: Quantum/Vidyut – 40T, 88T, 130T, 160T, 180T, 200T, 250T

High Efficiency

High Precision

Stable Performance

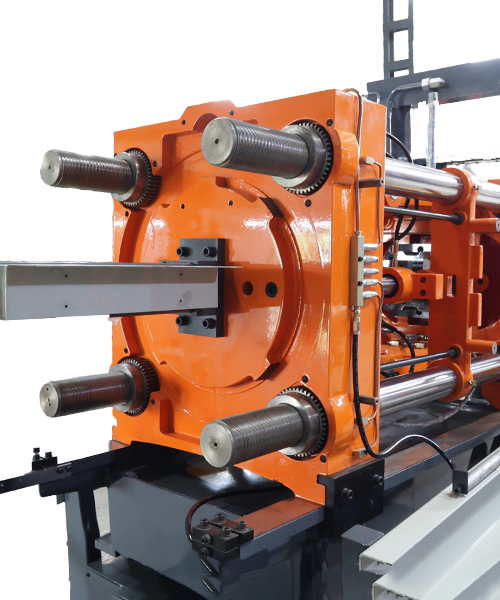

High-speed & Stable Clamping

Optional high-speed clamping system shortens cycle times to reach a higher OEE in the casting production.

Enhanced ductile cast iron platen with highest rigidity protects the die casting die and reduces flash. Chromium plated high strength steel tie bars with extended service life.

High Precision Injection

The optimized injection system with two stage injection control is suitable for high-quality productions.

Advanced Electronic Heating System

Equipped with advanced nozzle/gooseneck heating control system.

Fast Sensitive Control

Dry injection speed ≥5m/s, pressure and flow are controlled by a proportional valve and parameters can be set on the screen to save time in process stetting.

Products Made in Hot Chamber